By Nathan Seed, Application Sales Engineer at Vaisala

From glistening chocolate truffles to powdered and crystallized sugar and even the syrup we put on pancakes, indulgence in sweet delights begins long before a consumer opens the first heart-shaped box or bag of candy.

Behind each delightful taste, every velvety texture, and the perfect sweetness that defines these treats lies meticulous precision in monitoring across various applications to ensure consistency of quality. In a $1-plus trillion (and growing) industry, reliable measurements throughout the sugar cane and beet processing, syrup production, and confectionery manufacturing processes are vital for sugar mills and refineries, syrup producers, and chocolate and candy makers to churn out the highest-quality products while maximizing efficiency and profits.

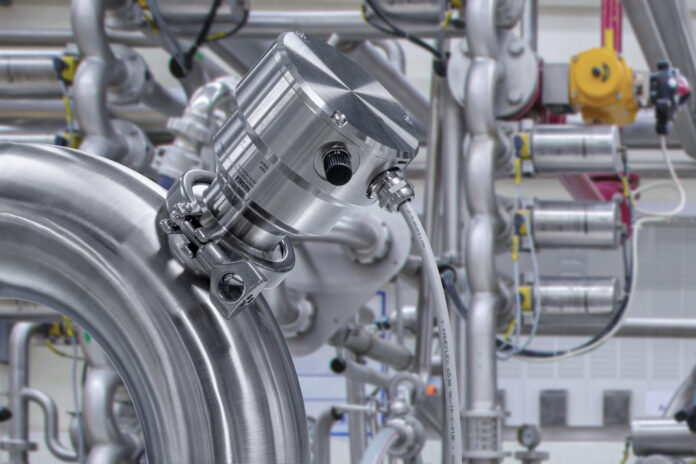

Continuous Brix measurement — facilitated by inline process refractometers — is an important innovation that takes the guesswork and human error out of manual processes with impressive results. Let’s explore how this technology empowers producers and processors to improve the efficiency of processes, sustainably optimize resources, and maximize yield while maintaining quality and eliminating costly unplanned shutdowns.

Sugar’s journey from harvest to sweet treats

Sugar comes primarily from two sources: sugarcane and sugar beets. Edible sugar manufacturing is a delicate process requiring stringent process control. Complicating the issue, sugar milling and refining is energy-intensive, so refiners increasingly integrate tighter process control based on reliable readings to achieve the greatest yields while reducing expenditure on raw supplies and steam usage.

The harvested sugarcane or sugar beets are processed to extract their raw juice, which undergoes multiple purification processing steps to remove impurities and solid particles. The clarified juice is heated to evaporate excess water, resulting in a concentrated solution. The solution is then cooled, causing sugar crystals to form and separate from the remaining liquid matter. These sugar crystals may experience further processing for refinement, bleaching, and granulation to achieve specific textures and sizes.

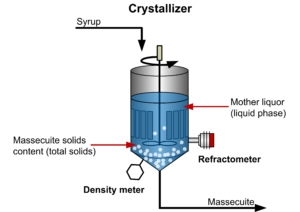

Continuous Brix measurement occurs at evaporators that boil off water, melters that combine liquid sugar solutions, and crystallizers that spur sugar crystal formation, with each stage demanding precise control to ensure product quality and process efficiency.

Brix and mother liquor concentration are commonly monitored parameters in the vacuum pan as they control the crystallization process and, therefore, affect the end product quality. At the beginning of the strike, the process medium is pure liquid. Crystals are introduced only after the pan reaches the seeding point. After seeding, the Brix content increases as the crystal content increases, whereas refractometric concentration stays relatively constant.

Supersaturation is the driving force of crystal growth and is a function of several parameters. Outside the required range, crystals will stop growing or start conglomerating, requiring reprocessing.

Once the sugar reaches its final form — granulated, powdered, etc. — it can then be shared with syrup producers and various food and beverage manufacturers that need to control mixing and blending phases to guarantee the right flavor, shape, and texture of every product.

With precise process control significantly impacting consumer satisfaction and product quality, the foundation for sugary treats begins with accurate Brix measurement. Maintaining operational precision during cane and beet sugar processing and crystallization helps sugar processors optimize processes to increase the quality of liquid and crystal sugars and ensure liquid bulk sugar and molasses meet specifications.

Syrups preparation

Syrups — made from sugar crystals and other liquids — are commonly used in confectionery, beverages, and canned product production. Many confections and fillings like chocolate or caramel require the syrup solution to be concentrated to a high level by cooking and evaporating the water in a closed vessel and in vacuum conditions to reduce energy consumption. Obtaining precise Brix measurements related to syrups can help control the evaporation and blending operations in real time, assuring the final concentration meets quality requirements and the desired taste, texture, and appearance standards.

However, high temperatures and challenging vacuum conditions pose obstacles to obtaining reliable measurements. Sugar syrup solutions involve extremely high heat, so instrumentation must withstand temperatures up to 150° Celsius, or 300° F, to function accurately. Rapidly changing conditions demand quick data acquisition to ensure proper blending for color, taste, smell, etc.

Unquestionably, the specialized conditions of syrups preparation necessitate inline, accurate, repeatable process monitoring systems explicitly designed to continuously monitor the Brix level of the cooked solution to determine in real time when cooking should be stopped. From cost-efficiency to optimal processing times to strict final product quality control, inline, accurate, repeatable Brix measurement brings myriad benefits to sugar syrup preparation.

Sugar confectionery and filling

Sugar confectionery and fillings makers buy processed sugars or syrups to make their products. From candies and chocolate fillings to chewing gum, marshmallows, and other sweet desserts, sugary confections are rich in sugar and carbohydrates — and must maintain a particular shape or texture to prevent leaks or stickiness. Sugar confectionery and chocolate fillings producers mix and dilute ingredients and concentrate the sugar content in their products to the desired level by cooking and evaporating the water.

Since the final Brix of the solution determines the final product’s flavor, consistency, and overall quality, sanitary process refractometers provide real-time information to follow the cooking progress and determine the endpoint to ensure consistent product quality. Ideal for installations in vessels with scrapers and mixers, inline process refractometers eliminate the need for sampling, prevent process disruptions and save valuable processing time.

Benefits of inline, continuous, reliable Brix measurement accuracy

Continuous and reliable Brix measurement delivers multiple benefits that extend well beyond simple process control throughout the cane and beet sugar processing, syrup production, and confectionery manufacturing processes.

Today’s most advanced process refractometers can be installed anywhere in the pipeline, enabling reliable process control and profitable and sustainable production while maintaining the highest product quality and safety standards.

Continuous inline liquid concentration monitoring provides a range of benefits:

- No time-consuming manual sampling

- Minimal batch-to-batch variation

- Consistent product quality

- Improved customer satisfaction

- Optimized raw material usage and processing and preparation time

- Compliance with product specifications and food safety regulations

- Accurate, drift-free measurement not affected by air bubbles in mixed sugar solutions

Precise liquid concentration measurements translate directly into production efficiency and maximized profits by decreasing discarded ingredients, failed batches, and repetitive steps while delivering consistent taste, texture, mouthfeel, and appearance of candies. The level of knowledge into the confectionery production process that inline refractometers unlock transforms into substantial savings while upholding standards for delectable treats.

The science of sweet success

As competition between sugar mills and refineries, syrup producers, and chocolate and candy makers increases, the journey from raw ingredients to delightful confections highlights the indispensable role of accurate process monitoring and Brix measurements in various applications. Continuous, repeatable inline measurements maximize process efficiency and product quality at every step of the process — from careful evaporation to controlled crystallization and optimized blending.

Through precise process control, sugar processors, syrups preparers, and food and beverage manufacturers underscore their commitments to quality control and consumer care. When production is guided by robust instrumentation delivering accurate data, life’s sweetest moments will be better celebrated with sweet treats perfected through precision control.

Nathan Seed is an Applications Sales Engineer at Vaisala with over 5 years of experience in both project management and technical sales. He supports the Liquid Measurements partner network and end users in customizing solutions that meet the needs of a variety of regulatory and monitoring guidelines.

Nathan Seed is an Applications Sales Engineer at Vaisala with over 5 years of experience in both project management and technical sales. He supports the Liquid Measurements partner network and end users in customizing solutions that meet the needs of a variety of regulatory and monitoring guidelines.

Credit: Source link