Lakeview Farms is known for “creating a world of fresh, delightful foods” in the form of

Lakeview Farms is known for “creating a world of fresh, delightful foods” in the form of

fresh and convenient dips, desserts, and specialty products. The company started in 1988

with just one customer and a handful of employees who knew that Lakeview’s success and

growth depended on both delicious food products and unparalleled dedication to their

customers. Through the years, Lakeview Farms has continued to develop new products that

are enjoyed by consumers nationwide.

The challenge

Lakeview Farms was consolidating three plants into one. During that process, several operational problems began to surface, as well as transition-related confusion. Ultimately, they identified four concerns, all centered around maintenance:

“Our PM was spotty, only done when critical failures were seen,” said Todd Parker, Plant Engineer for Lakeview Farms. Using three-copy work orders and manila folders, maintenance records were filed in a cabinet, often never used again. Parker states, “Things were all written down, but never accessed. The next time PM needed to be done, the whole process started over. Our daily maintenance huddles used to be a pot of coffee and ‘What did you do last shift?” Parker said. “There was some direction, but not a whole lot more. There was a discussion with really no data and it was based on the most recent occurrence, not data-driven improvements.”

Additionally, there was no way to track machine uptime. The limited data was manually created, fallible, and inconsistent – making it hard to empower consistent OA and production.

The maintenance staff was also concerned with their handwritten carbon copy work orders, lack of support from the parts department team, and spending less than 50% of labor hours on actual machine maintenance activities. These factors were directly responsible for the high levels of overtime experienced within the maintenance team.

Lastly, because the three maintenance departments were operating on a reactive maintenance and repair schedule, the spare parts inventory was not sized right. This caused over $1 million in unknown spare parts inventory.

The solution

![]() After implementing L2L, Lakeview Farms instantly gained real-time visibility for schedulers and technicians. This visibility reduced reactive repairs and improved their overall preventative maintenance plans. L2L also enabled technicians to directly link the history of failures to the PM history, as well as monitor technician labor on each PM activity, making them sortable by machine and technician.

After implementing L2L, Lakeview Farms instantly gained real-time visibility for schedulers and technicians. This visibility reduced reactive repairs and improved their overall preventative maintenance plans. L2L also enabled technicians to directly link the history of failures to the PM history, as well as monitor technician labor on each PM activity, making them sortable by machine and technician.

With L2L, when a machine is scheduled for PM, the time window is set whether or not maintenance is needed. If there is no need for maintenance, that time can now be used for calibration or documenting other vital information into the system.

The result (in just 6 months)

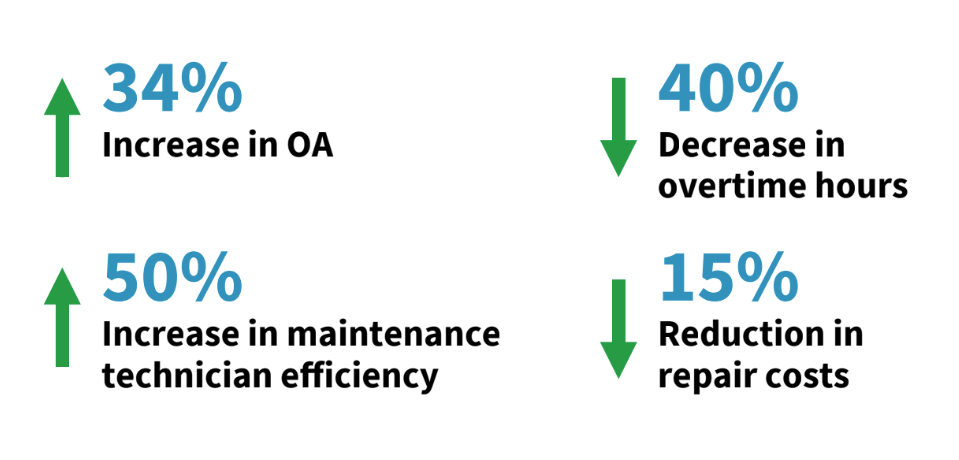

Just six months after implementing L2L, Lakeview Farms saw remarkable results. OA increased by 34% and employees finally gained accurate equipment history. Overall repair costs dropped by 15%. Maintenance technician efficiency improved from 50% to 75%, which resulted in a 40% decrease in overtime hours.

Just six months after implementing L2L, Lakeview Farms saw remarkable results. OA increased by 34% and employees finally gained accurate equipment history. Overall repair costs dropped by 15%. Maintenance technician efficiency improved from 50% to 75%, which resulted in a 40% decrease in overtime hours.

Finally, the overflowing spare parts warehouse was finally accurately inventoried with a go-forward plan to only purchase parts according to the preventative maintenance schedule. Having insight into the correct part meant higher savings and better uptime. That also reduced staff due to automatic ordering and parts management. All of which have gone straight to Lakeview Farms’ bottom line.

Credit: Source link