StePacPPC’s green packaging helps packers and shippers of produce transition from environmentally unfriendly ice-filled polystyrene foam and waxed carton boxes.

Tefen, Israel – Innovative Modified Atmosphere/Modified Humidity (MA/MH) packaging developed by StePacPPC is facilitating the transition away from ice-filled polystyrene and waxed carton boxes for packaging fresh broccoli and other vegetables for long-haul shipments in both the US and Japan.

The Otofuke Agricultural Cooperative in Japan (JA Otofuke) —a major broccoli producer—is already benefiting from StePacPPC’s Xtend® MA/MH bulk bags for shipping broccoli on its land journey from Hokkaido to Yokohama.

Polystyrene foam boxes filled with ice have been widely used for the domestic transport of many vegetables in Japan. While such packaging has excellent insulation properties and helps maintain low temperatures, it is not an environmentally friendly packaging material. Polystyrene foam is becoming increasingly shunned by retailers concerned about the ease with which it fragments, its persistence in the environment and the fact that it is non-recyclable. Polystyrene generates significant disposal challenges, prompting calls for it to be phased out and be replaced with more eco-friendly alternatives.

Many countries have already banned polystyrene entirely. Japan is placing growing regulatory emphasis on reducing the use of non-recyclable materials including certain types of polystyrene foam.

Likewise, in the U.S., waterproofed waxed carton boxes used for iced broccoli shipments are increasingly unwelcome. Their wax coating renders them unsuitable for paper recycling, relegating them to general waste. Worse, landfilled waxed cardboard can produce methane, a potent greenhouse gas. Certain states, such as California, have placed local bans on non-recyclable containers.

From a food safety standpoint, as the ice in the boxes melts, it is also conducive to microbial decay. Studies have shown that at any point in time, the amount of microbial colony forming units on iced broccoli is higher than on broccoli packed in MA/MH packaging. And, numerous studies have shown that as the ice melts, vitamin C from the broccoli leaches out. It also can be physically unsafe: Melting ice is not only messy, it creates potential slipping hazards.

“In our efforts to move away from polystyrene foam with ice and its inherent contamination risks, we considered various alternatives for maintaining freshness without using ice,” explains Akio Yamagishi, Manager of the Fruit and Vegetable Sales Department of JA Otofuke. “We tested various modified atmosphere packaging films, including the Xtend films from StePacPPC. After inspecting the condition of the broccoli upon arrival, Xtend outperformed the rest in both appearance and quality.”

The Xtend packaging films are built with modified atmosphere and moisture control properties. These work to slow respiration inside the packaging, inhibit ethylene (a plant hormone that promotes yellowing of broccoli), remove excess moisture, delay the aging processes, and slow the growth of microorganisms on broccoli. Its mode of action may also reduce the risk of foodborne illness associated with pathogens such as E. coli.

Climate positive, cost effective

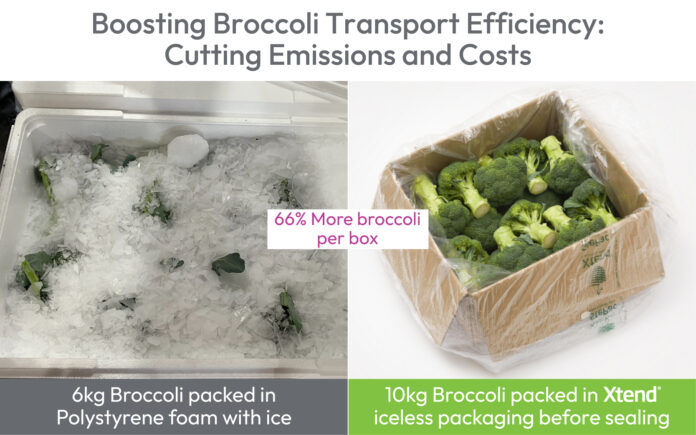

“We discovered multiple benefits to iceless Xtend packaging,” continues Otofuke’s Yamagishi. “First, it eliminates the space ice occupies, allowing us to transport 66% more broccoli per container. This slashes carbon emissions and transport costs, especially significant given the recent rises in shipping costs. With ice, each box holds only 6kg of broccoli; without it, we can pack around 10kg. In addition, one Xtend bag can hold 10kg of broccoli, making it more resource-efficient and eliminating the need for extra handling. The ability to transport ice less fresh broccoli across the continent on weight-constrained trucks has led to a net reduction in costs of more than 30%.”

Xtend is also being widely adopted in the U.S. for supplying fresh broccoli to the food service sector. “At a time when flexible plastic packaging is under the spotlight, we have, together with researchers at the Agrotechnology & Food Sciences Group at Wageningen University, demonstrated that our functional ‘lean and green’ packaging solution reduces the carbon footprint by approximately 40% in shipments from Salinas Valley on the West Coast of California to New York on the East Coast, demonstrating a positive environmental impact,” informs Gary Ward, Ph.D., CTO for StePacPPC.

“It also has proven capabilities for preserving both the quality and nutritional value of fresh broccoli during prolonged storage, extending shelf life, minimizing waste, and enhancing food safety,” Ward concludes. “Our Xtend bulk packaging also successfully preserves other produce traditionally shipped on ice, such as bok choy and green onions.”

About StePacPPC

StePacPPC specializes in functional packaging for fresh produce. Its globally recognized brands include Xtend®, Xgo™, Xflow™ and Xbloom™ modified-atmosphere/modified-humidity packaging solutions. These solutions reduce weight loss, slow respiration and aging, and inhibit microbial decay, while prolonging storability and shelf life. They are supported by a wealth of post-harvest expertise for enhanced performance and sustainability.

Company Contact:

StePacPPC

Mrs. Hila Nagel

Marketing Communications

Tel: +972.4.612.3500

[email protected]

www.StePacppc.com

Press Contact

NutriPR

Ms. Liat Simha

[email protected]

www.nutripr.com

Twitter: @NutriPR_

Credit: Source link