By Wendy Booker, VP of Marketing for SupplyOne

In today’s fast-moving market, manufacturers are increasingly turning to automation to optimize their operations, reduce costs, and stay competitive. SupplyOne is leading the way in delivering innovative packaging automation solutions that are tailored to meet the specific needs of manufacturers in diverse industries.

Automating packaging processes can bring a wide range of benefits, including increased productivity, reduced labor costs, improved product consistency, and faster speed-to-market. These systems allow companies to scale their operations more effectively while maintaining high levels of quality and efficiency. In a business environment where speed and precision are paramount, automation can become a critical component in maintaining a competitive edge.

SupplyOne’s automation capabilities provide companies with measurable improvements. Below, we explore how several manufacturers have harnessed automation to transform their packaging processes.

Dairy and cheese processor eliminates co-packing and improves consistency

A dairy and cheese processor with two plants in different states faced significant challenges with inconsistent packaging and inefficient automation. The company relied on external co-packers, which resulted in uneven product presentation and slow production timelines. Additionally, logistical issues between the plants and a lack of in-house expertise hampered efforts to create an efficient automation strategy.

A dairy and cheese processor with two plants in different states faced significant challenges with inconsistent packaging and inefficient automation. The company relied on external co-packers, which resulted in uneven product presentation and slow production timelines. Additionally, logistical issues between the plants and a lack of in-house expertise hampered efforts to create an efficient automation strategy.

SupplyOne partnered with the company’s key stakeholders and introduced new automated packaging equipment. By eliminating the need for co-packing, the company gained greater control over their production process, which ensured consistency across all products, regardless of their origin. Automation not only improved production efficiency but also allowed for faster speed-to-market for new products. This enabled the company to expand into additional states and launch a private-label program, generating additional revenue. The improvements in automation gave the company newfound agility and control over their operations.

Flour and wheat products manufacturer drives sales growth with automation

A manufacturer of flour and wheat products operating in both Mexico and the United States was struggling with rising production costs and outdated packaging technology. These issues were a byproduct of unnecessary inefficiencies, high labor costs, and an inability to meet growing market demand. The company’s production line was limited by old technology, and they lacked the expertise to implement automation.

A manufacturer of flour and wheat products operating in both Mexico and the United States was struggling with rising production costs and outdated packaging technology. These issues were a byproduct of unnecessary inefficiencies, high labor costs, and an inability to meet growing market demand. The company’s production line was limited by old technology, and they lacked the expertise to implement automation.

To address these challenges, SupplyOne introduced a high-performance automation solution that enhanced packaging functionality and retail packaging design. By automating key aspects of the production line, the manufacturer was able to streamline their operations, significantly reduce labor costs, and increase their overall sales. As a result, the company saw a 300% increase in retail product sales, avoided additional advertising expenses, and improved their overall packaging performance. This combination of automation and improved packaging design allowed the company to meet growing demand in both U.S. and Mexican markets.

Pharmaceutical manufacturer resolves bottlenecks and boosts productivity

An OTC pharmaceutical manufacturer was facing a bottleneck in their packaging line caused by manual bundling and shrink-wrapping processes. Despite investing in automation for most of their production line, the manual labor required for bundling was slowing down productivity and causing inconsistent packaging quality. These inefficiencies led to increased labor costs and slower turnaround times.

An OTC pharmaceutical manufacturer was facing a bottleneck in their packaging line caused by manual bundling and shrink-wrapping processes. Despite investing in automation for most of their production line, the manual labor required for bundling was slowing down productivity and causing inconsistent packaging quality. These inefficiencies led to increased labor costs and slower turnaround times.

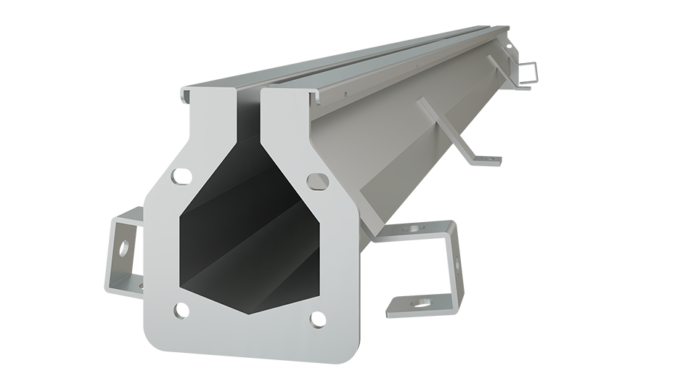

SupplyOne introduced the Array Pack AP-25, an automated stacker and bander that seamlessly integrated with the manufacturer’s existing packaging line. The introduction of the Array Pack automated the bundling process, which eliminated the bottleneck and increased the overall productivity of the line. The company experienced a 25% increase in throughput productivity and was able to cut labor costs by half. In addition to the increased efficiency, the automation improved packaging consistency, which resulted in more satisfied customers. The manufacturer’s ability to meet growing production demands was significantly enhanced through this automation solution, freeing up resources to focus on more strategic initiatives.

Automation delivers more than efficiency

These case studies highlight how SupplyOne’s packaging automation capabilities have transformed production lines and improved bottom lines across industries. By introducing state-of-the-art equipment and customizing solutions to meet specific operational needs, SupplyOne helps manufacturers reduce costs, increase throughput, and enhance product quality.

For companies struggling with bottlenecks, labor costs, or inconsistent packaging, SupplyOne offers a pathway to more efficient and scalable operations through innovative automation solutions. Whether it’s redesigning a production flow, integrating advanced equipment, or eliminating manual processes, SupplyOne’s approach to packaging automation ensures that their clients can focus on what matters most—growing their business.

Contact a SupplyOne packaging automation specialist today to learn how automation can revolutionize your production line.

Credit: Source link